Detailed Product Description

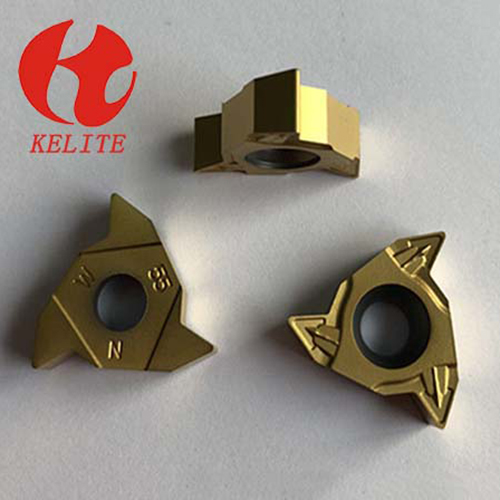

Threading Inserts CVD/PVD Coating Carbide Inserts CNC cutting tools

Description:

1. ISO metric thread(with end)

2. General Pitch thread(with end)

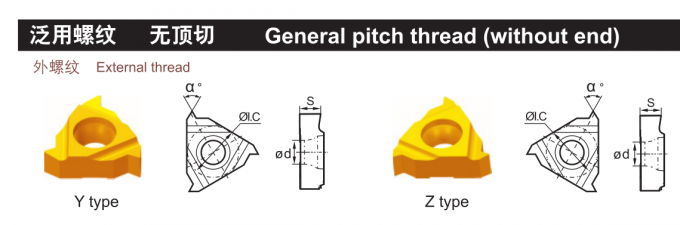

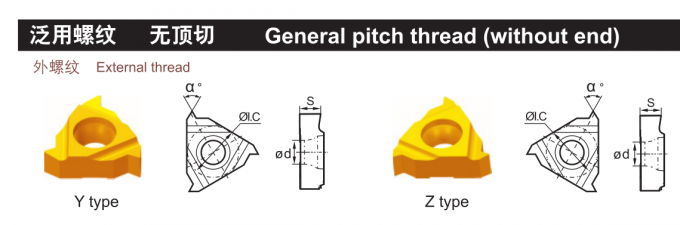

3. General pitch thread (without end)

4. External thread whitworth thread(with end)

5. Unified thread (with end)

6. British Standard taper piper thread (with end)

7. American stand taper piper thread(with end)

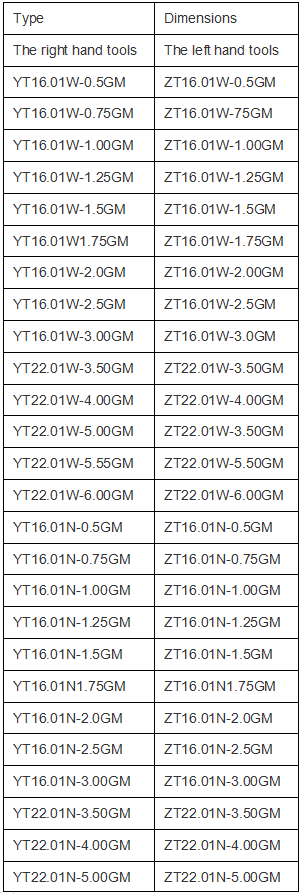

8. External thread and Internal thread

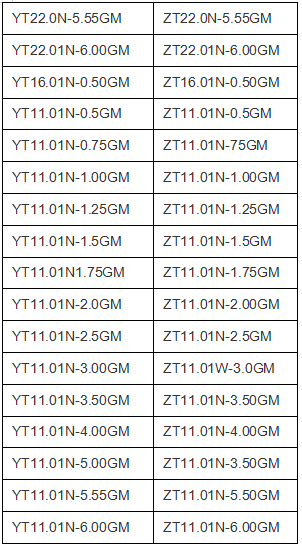

9. Y type and Z type

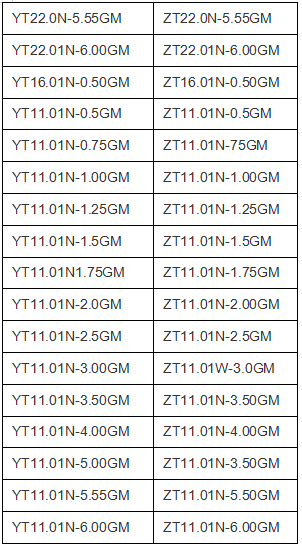

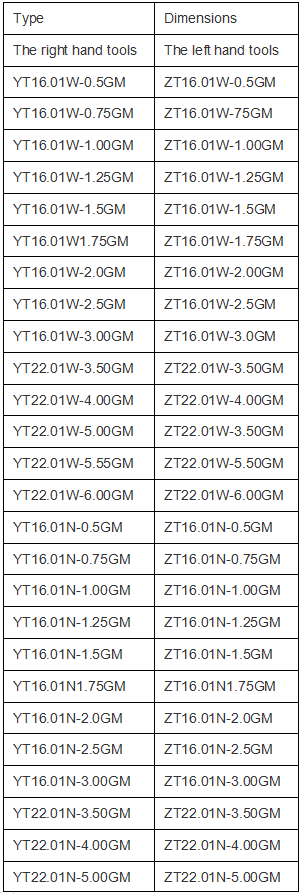

10. Right hand and left hand tools

Applications:

Including type(Right hand and left hand)basic dimensiolns ,applicable inserts ,spare parts.

Including (right and left hand)basic dimensions,stock, types , standard tolerance class

Shape of inserts: Length : 11,16,22 mm.

How to select threading tools

1. Structure of expernal threading and internal threading accroding to machine type.

2. Categorized as expernal threading and internal threading.

3. Separately listed out accoring to series.

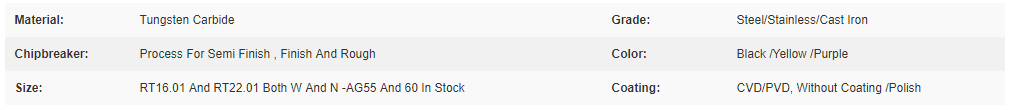

Grade of threading:

KT8205 grade similar to YBG201 , has been upgraded to nc-TiAIN

Golden Tin Coating on the surface can diminish frictoin and help identity abrasion.

The inner layer of nc-TiAIN coating has outstanding wear resistance.

Tin and PVD coated alloy has good toughness and wear resistence.It is a special grade for machining of carbon steel, stainless steel and cast iron steel ,etc

Function and applications of wiper for threading inserts.

Reduce machining procedures:

Before threading ,it is necessay to finish the treaded part ,which could done by wiper to make the major diameter achieve the desired dimensions and surface quality.

Automaticlly remove burrs:

The wiper on threading realizes finishing on major diameter of machined threading, making it unnecessary to remove burrs after machining and ensuring good surfce quality.

Outstanding features of threading inserts chipbreaker.

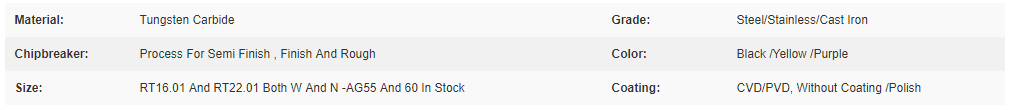

Specification:

Feature Advantages:

1. The threading insert series has special treatment on cutting edge, with better surface finish, sharp cutting edge, and small cutting resistance. The new nano-coated grade KT8205, which is specially designed for thread processing conditions, optimizing the coating structure, improving the stress state of the coating, enhancing the bond strength between the coating and the substrate, and making a longer service life of the threading insert.

2. Outstanding chipbreaking performance.

Corrugated chipbreaker on the rake face of threading inserts lift the chip flow, direct it's movement along the front of chipbreaker and control it's shape for a small curvature radius.

Chipbreaker design with good generality.

Because of the specil chipbreaker structure ,the moving , curling and breaking of chips are mainly controlled by the insert itself , therefore , desirable results can be obtained for different materials and with different cutting parameters.